Product development and prototypes are commonly handled in three different ways.

- Subtractive manufacturing – a person or CNC machine continuously cuts material away from a solid piece, such as metal.

- Injection molding – heated material is injected into a mold and can produce products in large quantities.

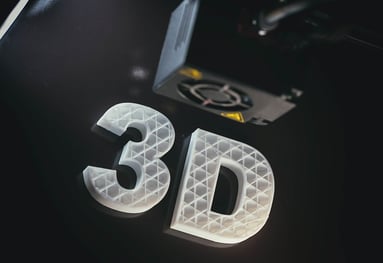

- Additive manufacturing – also known as 3D printing, produces products and prototypes by adding material layer-by-layer.

What is 3D Printing

3D printing is used in just about every industry. From manufacturing tools, dental products, movie props, and reconstructing forensic evidence. It starts with a 3D model design using a 3D/CADsoftware tool, creating a printable 3D file, and slicing the file into thousands of layers ready for printing. The additive manufacturing process is the opposite of subtractive manufacturing as it creates successive layers of material to build an object.

8 Benefits of 3D Printing

Low Cost

CNC machining or injection molding requires multiple machines and experienced operators and technicians. 3D printing saves time and saves money. An operator doesn’t have to attend to the machine from start to finish, making the labor cost significantly lower. Additionally, you pay for less material because the part is built layer-by-layer from the ground up, and less material becomes waste.

Flexible Design

3D printing allows for more complex designs and prints than subtractive manufacturing or injection molding due to their design limitations. In traditional manufacturing, each modification or addition requires a new mold, tool, etc., to be manufactured. 3D printing allows the creation of parts, textures, color mixtures, and mechanical properties impossible for traditional processes and can create almost anything within the printer’s build volume.

On-Demand Printing

3D design files can be stored on your computer or cloud and ready for printing whenever there’s a demand. You can save time, money, and space as there’s no need to stock or manage high levels of inventory.

Lightweight and Durable

Most 3D printed materials use plastic. Plastics are lightweight, durable, and often critical for efficiency and effectiveness in aerospace, aviation, medical devices, etc.

Fast Prototyping and Testing

Prototyping that used to take days can now only take a few hours. Each stage of the production process is faster, and modifications can be more efficient. You can market test or demo a product, gather feedback, avoid the risk of expensive upfront investments, and the risk of customers or business stakeholders not understanding your product vision.

Sustainability

Because 3D printing is an additive process, the production only requires materials built into the part itself. There’s little to no waste compared to the subtractive processes that can leave large pieces of material and require long cleanup times.

Quality

A traditional manufacturing process includes multiple steps from design to finished product. The order of these steps, the multiple technologies, and the machines involved can affect the design quality. 3D printing compresses the numerous steps into one and avoids the interaction of various machines and operators. As soon as a design is ready, it can be sent to a printer and built in one step.

Low Risk

3D printing enables you to design a concept and make it a reality faster than anything else. Due to the speed and lower cost of 3D printing, it’s also a less risky process. Even small changes to a mold or CNC process can increase the production cost and time. You can be confident your 3D printed design is a production-ready prototype before investing in expensive manufacturing equipment or processes.

Rapid Axis has the experience and capabilities to provide you with the best 3D printing services in the industry. We offer SLA, FDM, and SLS printing for all your prototyping needs with the fastest lead times, guaranteed. Call or email today and receive a free quote in just a few hours!