Intro

Adding a draft angle could make or break your designed aluminum box. However, a lot of people don’t know how important this factor is, and they don’t know where to start. In this quick guide, we’ll explain everything you need to know about draft angle requirements for die-cast aluminum box parts.

What Is a Draft Angle?

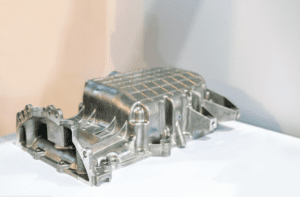

A draft angle is something that you’ll need to think about when you’re designing an aluminum die-cast part. It’s especially important in boxes that have vertical, upright walls that are perpendicular to the base.

So, what is a draft angle? It’s the slight slope that you’ll notice on the sides of a part. If a part has a 10-degree draft angle (which is an extreme angle), then you’ll see a taper or incline along the walls, and the top will be further out than the bottom.

Why Draft Angles are So Important

This might seem like an odd term, but it’s critical for die-cast parts. At the end of the die-casting operation, you need to get the cooled, solid piece of aluminum out of the recessed mold. If there is no draft angle, and the walls are all 90-degrees, then the part will get stuck — ejection becomes a lot trickier.

With a stuck part, it’s very likely that the die caster will damage the part trying to remove it, and this is hard to avoid.

However, it all gets avoided with a very slight draft angle. With this slope along the walls, your part can get removed very easily, since there is more clearance along the top of the die.

Are Draft Angles Used for All Die-Cast Metals?

When it comes to die-cast operations, you can typically choose zinc or aluminum for the part. With zinc, you don’t have to worry as much about draft angles. Something as low as 1/2 of a degree is often overkill for a lot of operations. A lot of manufacturers don’t even add a draft angle and they don’t run into issues with ejection.

Really, it’s just aluminum that you have to worry about — it tends to be a bit stubborn.

The Right Draft Angles for Die-Cast Aluminum Parts

Picking the perfect draft angle depends on a few things. If the cavity is really deep, you need precision-grade parts, or there are multiple sides to the mold, then you might need to add a more generous draft angle.

In general, we suggest a 2-degree draft angle for cores, and a 1/2-degree draft angle for the cavity.

With these angles, we’ve found that our die-cast aluminum parts can be removed without prying and damaging the parts.

Which Walls Get a Draft Angle?

To be more clear, we’re only talking about the parts that are parallel to the direction of the die draw. If you’re looking at a box with no lid, then the draft would get applied to the four upright faces, since those are all parallel to how the material gets added.

If you’re looking at a U-channel, then it would be the two uprights.

The flat bottom face doesn’t get a draft angle because that won’t impact how hard it is to remove the aluminum after it cools in the die. Sure, it’s easier to remove a pizza-shaped piece if it’s poured with the tip down, but that doesn’t mean that you should add an excessive draft angle to every mold you design — flat base plates are perfectly okay.

Conclusion

Now that you know more about draft angles, you can make more successful die-cast aluminum boxes. Of course, the other part of the equation is picking the right die-casting partner. At Rapid Axis, we offer full-service die-casting operations. Reach out today for a free quote or to learn more.