Intro

Designing a part out of sheet metal is very different than designing a part out of thicker stock metal. With sheet metal, there are different rules you have to understand, and different manufacturing methods that will be used in the machine shop.

In this guide, you’ll learn some important tips to remember for your next sheet metal project. We’ll teach you ways to design smarter sheet metal enclosures, which will save you time and money during your next project.

Use the Right Material

It all starts with the material choice. Not all sheet metal is alike, and picking the wrong material to start with can actually ruin your project. In most cases, you will be choosing between aluminum, stainless steel, and galvanneal.

To make your selection simpler: use stainless if you need a stronger enclosure, aluminum if you need a lighter and less expensive enclosure, and galvanneal if you need a more durable enclosure. There are a lot of other pros and cons of each material that we can tell you about when you reach out for a quote through Rapid Axis.

Understand Your Wants and Needs

In the design world, you would call these “constraints” and “nice to have’s”. The bottom line is that you need to know what is required from your enclosure. An example of this is that your enclosure might need access holes in certain areas, but you want the enclosure to be colored red.

In this scenario, you have the ability to change your mind about the color if you find out it adds price and time to the build.

If you’re not sure about the constraints of your enclosure, you should spend some time and have some meetings before getting into the design work.

Stick with Simple Shapes

With sheet metal fabrication, it’s best to stick with simple shapes. This is even more critical when it comes to enclosures.

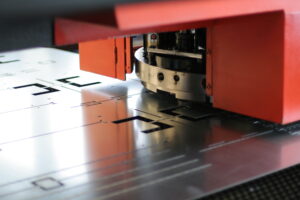

Having a hexagonal metal enclosure is significantly harder to make and more expensive than a standard six-walled enclosure. What shapes do sheet metal designers typically use? Squares, L’s, U’s, and F’s are very common and easy to make. Plus, laser cutters are great at making simple shapes very quickly.

Try to Provide a Flat Layout

With modern 3D CAD programs like SolidWorks and Inventor, you can convert your 3D sheet metal enclosure into a flat layout. The flat layout is what a machinist would need to quickly and efficiently make the part.

If you provide a 3D model to us, we’ll have to spend the time doing this step ourselves which can add a lot to your quote. Another benefit of providing a flat layout is that you can look at the shape to see if you made any mistakes during the 3D modeling.

For instance, you might be asking for a bend that’s not physically possible due to the shape of your sheet metal. As you try to “unfold” the shape in your CAD program, it will give you an error. This is your indicator that it’s time to re-draw the part.

Finding this out earlier can save you time and money during the fab process.

Don’t Forget the Bending Radius

It’s impossible to bend a piece of sheet metal without creating a bending radius. In other words, your enclosure won’t have square angles after being bent. This isn’t a big deal visually, but you need to make sure your design accounts for these bending radii.

If your drawing assumes square and flush corners, then your flat layout will be a little bit too long. After we bend the part in our shop, there might be interferences that you didn’t account for.

As a rule of thumb, the internal bending radius should always be at least 1x the thickness of your sheet metal. If your sheet metal is 0.1019 inches thick (aluminum 10 gage), then the internal radii must be at least 0.1019 inches.

Pick the Perfect Fabrication Partner

Not all machine shops are equipped to handle sheet metal projects. Before getting too far, you should shop around for the best sheet metal fabrication partner. We say “fabrication partner” instead of machine shop, because you should always be looking for a long-term partner, not just a one-off fabricator.

At Rapid Axis, we provide full-service sheet metal fabrication and we’re always on your side. If we spot something funny in a drawing or design, we’ll point it out and ask for clarification before we start cutting. This saves you money on every project.

What About Finishing?

Another thing to consider is the finishing steps. Do you want your enclosure to be polished, painted, powder coated, anodized, or plated? The machine shop would need to know this before they start cutting and bending your sheet metal part.

This detail would also show up in your quote.

Always Start with a Prototype

Sheet metal is one of our favorite materials to prototype with. An experienced machinist knows how to quickly play with sheet metal to make a prototype in no time at all.

If you need to make a dozen enclosures, it might help to start with a single enclosure using your design. Once you get it in your hands, you can see where you should tweak the design. You can also check the fit and look for ways to optimize your enclosure.

Rapid Axis can handle your prototyping or full-scale enclosure needs.

Conclusion

Now you know how to make a high-quality sheet metal enclosure. Our design tips will help expedite your project and keep the quotes low. For more design tips, check out the rest of our blog. For a team of expert-level machinists, consider Rapid Axis. We can handle your sheet metal enclosure fabrication, and we provide a wide range of finishing steps. Get a free quote today.